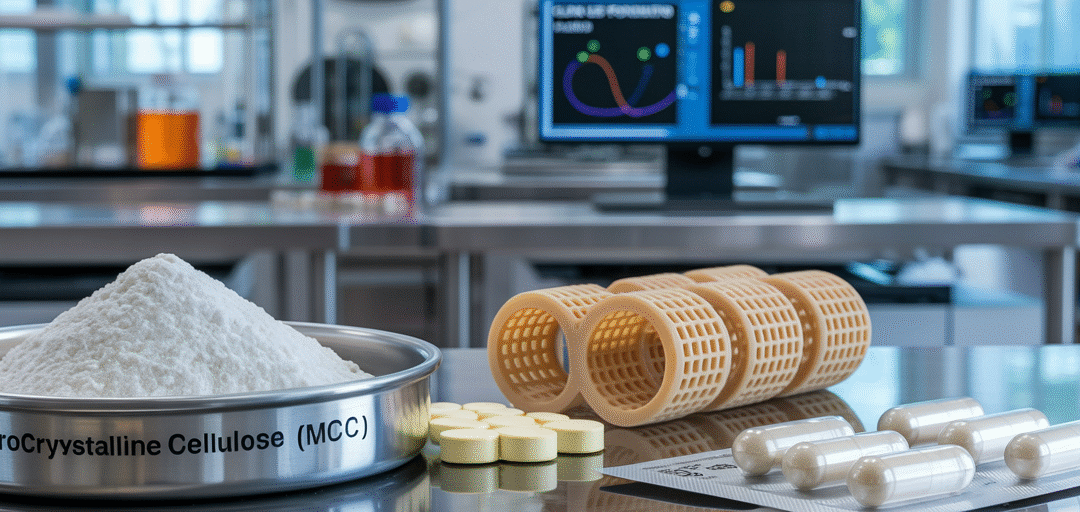

Microcrystalline cellulose (MCC) has quietly become one of the most strategically important excipients in modern pharmaceutics and nutraceuticals. It’s the backbone of direct-compression tablets, the bulking agent behind clean-label capsules and chewables, and an enabler of new digital-manufacturing workflows such as 3D printing of personalised medicines. Commercial momentum is strong: multiple market trackers place the global MCC market around the $1.3–1.4 billion mark in 2024, with trajectories that cluster near $2.7–2.8 billion by 2034, implying roughly ~6–7% CAGR. In parallel, regulators have harmonised pharmacopeial monographs across the major regions, and quality groups have sharpened good-practice guidance for excipient manufacturers and distributors—reducing risk for brand owners and CMOs.

This guide is written for formulation scientists, procurement leads and operations managers. It moves from market numbers to formulation science (what MCC actually does in a tablet), then into the frontier—3D printing and continuous manufacturing—before surveying sourcing choices (wood vs non-wood) and the supply-chain and regulatory forces likely to shape the next decade. Two concise tables and a quick chart capture the essential data.

Executive snapshot: why MCC remains a default excipient

Functionally rich. MCC is a partially depolymerised cellulose with a porous microstructure that delivers compressibility, binding, and wicking-driven disintegration—a rare combination that simplifies direct compression and wet granulation alike.

Regulatory familiarity. Harmonised monographs exist across USP–NF, Ph. Eur., JP, and MCC is widely listed in regulatory databases for oral dosage forms.

Clean-label pull. As E460(i), MCC supports “natural” and clean-label narratives in nutraceuticals and some food-adjacent products, with strong safety assessments from competent authorities.

New tech fit. MCC’s powder mechanics, thermal robustness and water affinity make it a leading solid matrix for 3D printing of tablets in extrusion-based systems and as a rheology modifier in semi-solid printing.

Market numbers you can plan around

A note of caution first: published figures vary by scope (merchant MCC vs downstream value, and whether food and personal-care are counted alongside pharmaceuticals). However, most reputable trackers align on the following shape:

2024 market base: roughly $1.3–1.4 billion

2034 outlook: around $2.7–2.8 billion

Implied CAGR (mid-2020s to mid-2030s): about ~6–7%

Top end-uses by value: pharmaceuticals and nutraceuticals typically command the largest share, with food, personal-care and other industrial uses following

Regional dynamics: Europe and North America rank high on pharma value density; Asia-Pacific leads on volume and capacity additions

Chart — Indicative global MCC revenue trajectory (2024 → 2034)

US$ billions

2.8 | █

2.6 | █ █

2.4 | █ █ █

2.2 | █ █ █

2.0 | █ █ █

1.8 | █ █ █

1.6 | █ █ █

1.4 | █ █ █

1.2 | █ █ █

1.0 | █ █ █

0.8 | █ █ █

0.6 | █ █ █

2024 2026 2028 2030 2032 2034

(Illustrative band consistent with ~6–7% CAGR)

What this means for buyers: plan for steady price-and-demand growth, with sporadic tightness when pulp derivatives tighten or when capacity expansions lag regulatory demand (e.g., new generics or weight-management categories taking off). Dual-source across at least two pharmacopeial-compliant producers where possible.

Formulation science: how MCC actually works in your tablet

The microstructure that does the heavy lifting

MCC is produced by controlled acid hydrolysis of α-cellulose followed by purification, washing, and drying. The process exposes microfibril bundles and crystallites, creating a porous, highly compressible powder with a large specific surface area. When you compress MCC, plastic deformation dominates over brittle fracture: particles deform and form strong interparticulate bonds, giving tablets high tensile strength at relatively low compaction forces. On contact with water, MCC’s capillary network drives wicking, which accelerates disintegration—even when you haven’t added a dedicated super-disintegrant.

Practical upshot: MCC reduces your excipient count. In many direct-compression formulations it acts concurrently as diluent, dry binder and disintegrant, with a bonus of improving blend flow if you select the right grade.

Grades and why they matter

Commercial grades are typically designated by number (e.g., PH-101, PH-102, PH-200), which acts as a proxy for median particle size and flow. Smaller grades (e.g., PH-101) compact beautifully but flow less readily; larger grades (e.g., PH-200) improve flow at a small cost to compactability. Co-processed MCC (e.g., with colloidal silica or crospovidone) exists to further tune flow, disintegration, and lubricity for high-speed direct compression.

Table 1 — Representative MCC grade guide (illustrative)

| Grade family | Typical D50 (µm) | Flow behaviour | Compaction profile | Where it shines |

|---|---|---|---|---|

| PH-101 | ~50 | Moderate | Excellent (high plasticity) | Small tablets, actives with high cohesiveness |

| PH-102 | ~100 | Good | Very good | General DC tablets; balanced choice for many APIs |

| PH-200 | ~180 | Very good | Good | High-speed DC; blends needing flow help |

| Co-processed MCC | Varies | Tailored (often very good) | Tuned | Low-lube systems; fast disintegration goals |

Exact specs vary by supplier; verify with CoA and in-house characterisation.

Lubrication, moisture and compatibility

Lubricants. MCC tolerates magnesium stearate reasonably well, but prolonged over-mixing can reduce tablet strength. If you push speeds or run high-load actives, consider sodium stearyl fumarate or split-addition of lubricant to protect tensile strength.

Moisture. MCC is slightly hygroscopic; LOD impacts compressibility and disintegration. Tight control of conditioning (or a brief pre-drying step) can stabilise tablet mechanicals.

Compatibility. Being non-ionic and inert, MCC rarely shows chemical incompatibilities, but adsorption on its porous surface can retard dissolution for poorly soluble actives—something to monitor with high surface-area grades.

Beyond tablets: MCC in capsules, ODTs and multiparticulates

Hard-shell capsules. MCC is a popular filler that maintains capsule weight variability and improves plug formation. Pair with glidants (colloidal silica) when actives are fine or cohesive.

ODTs (orally disintegrating tablets). MCC supports wicking and friability control. Many ODTs rely on MCC with super-disintegrants (crospovidone or croscarmellose sodium) to meet <30 s disintegration while maintaining acceptable hardness.

Pellets/granules. As a dry binder in extrusion–spheronisation, MCC is close to indispensable: it imparts plasticity and water-handling that enable robust, spherical pellets for multiparticulate dosage forms.

MCC and 3D printing: from proofs-of-concept to pilot lines

3D printing is redefining dosage design, enabling patient-specific strengths, novel release profiles and on-demand manufacturing. MCC plays several roles across printing modalities:

Direct powder extrusion (DPE). Powder blends are fed and extruded without prior filament production. MCC’s compressibility and wicking help create extrudable feedstocks and enable printed mini-tablets with controlled release profiles.

Fused deposition modelling (FDM) adjunct. While FDM relies on thermoplastic polymers, MCC-containing composites can modulate mechanical properties and disintegration in hybrid matrices.

Semi-solid extrusion (SSE). As a rheology modifier, MCC can stabilise pastes for extrusion and set the balance between shape fidelity and disintegration speed.

Takeaways for formulators: start with DPE if you want to leverage your existing direct-compression know-how. Optimise particle size distribution, binder fraction, and moisture; compendial MCC grades give you a pharmacopeial foundation when you advance to clinical material. Validate printed parts for content uniformity, hardness, friability, and dissolution like any batch-made tablet.

Clean-label and nutraceuticals: the E-number that earns its place

For nutraceuticals and some food products, the clean-label conversation is pragmatic: fewer unfamiliar chemicals, minimal synthetic processing, and strong safety credentials. MCC (E460(i)) fits this story. It’s derived from plant cellulose and assessed as safe at reported uses and levels by leading food-safety bodies. It also supports sugar and fat reduction through mouthfeel and bulking while maintaining chewability in gummies and tablets. That’s why you see MCC in fibre-fortified chewables, sports nutrition, and “natural” multivitamin tablets.

Sourcing strategy: wood vs non-wood, and why it matters

MCC is traditionally produced from wood pulp (often spruce, pine, or hardwood blends). But a rich literature and a growing roster of suppliers demonstrate viable non-wood routes:

Cotton linters

Sugarcane bagasse

Corncob and cereal straws (wheat, rice)

Sisal, flax, jute and other bast fibres

Aquatic biomass (e.g., water hyacinth in proof-of-concept studies)

Why look beyond wood?

Geography & resilience. Non-wood sources can localise supply in regions without robust forestry, cutting lead times and currency risk.

Sustainability. Upcycling agricultural residues (e.g., bagasse) lifts circularity metrics and reduces waste-burning.

Performance nuance. Non-wood MCC can match PH-101 benchmarks on flow, compressibility and tablet tensile strength when produced under validated conditions.

Buyer’s caution: non-wood routes must meet identical pharmacopeial criteria. Demand full change-control, traceability, and comparable impurity fingerprints (ash, metals, residuals) before qualification.

Table 2 — Sourcing considerations at a glance

| Criterion | Wood-based MCC | Non-wood MCC (e.g., bagasse, linters) | What to verify |

|---|---|---|---|

| Availability & scale | Global, mature | Regionally variable; growing | Capacity, dual-source options |

| Sustainability | FSC/PEFC forestry chains common | Strong circularity story (residues) | LCA boundary, certifications |

| Functional parity | Established across grades | Proven parity in peer-reviewed studies | Tensile strength vs compaction, PSD |

| Regulatory pathway | Clear, harmonised | Clear if monograph met; supplier-specific | Full CoA, change-control, pharmacopeial compliance |

| Cost drivers | Pulp market exposure | Collection/processing of residues | Long-term price stability contracts |

Quality and compliance: what your auditors will ask first

Pharmacopeial compliance. MCC has harmonised monographs across USP–NF, Ph. Eur., JP. Check identity, pH, loss on drying, degree of polymerisation and microbial limits as specified in each code.

Excipient GMP. Insist on manufacture under IPEC-PQG Good Manufacturing Practices for excipients. Extend this to Good Distribution Practice (GDP) for re-packers and logistics partners.

Regulatory familiarity. Use the FDA Inactive Ingredient Database (IID) to benchmark prior use levels per route and dosage form in approved products. This streamlines risk assessments for ANDA/NDA work.

Supply-chain agreements. Quality agreements should define change-notification thresholds (e.g., source pulp change, plant relocation), analytical methods, and stability commitments.

Stability & packaging. MCC is stable when protected from moisture; specify lined fibre drums or HDPE with desiccant for long storage, and control warehouse humidity.

Practical formulation playbook

Pick the grade first, not the lubricant. Choose PH-102 if you want a conservative blend of flow and compressibility; go smaller (PH-101) for tiny tablets or cohesive actives; larger (PH-200) for high-speed presses.

Tune disintegration with water seekers. MCC already wicks; adding crospovidone or croscarmellose sodium in low percentages often unlocks fast disintegration without sacrificing hardness.

Watch magnesium stearate time. Keep blend times tight (<2–3 minutes after lube addition) unless you’ve validated tensile strength at line-time.

Moisture is a dial. Slightly lower LOD usually tightens tablets; too dry can hurt disintegration. Aim for a controlled, reproducible window.

For 3D printing (DPE). Screen PSD, binder fraction (e.g., MCC with a plasticiser or polymeric binder), and line speed; characterise printed parts with standard QC (CU, hardness, friability, dissolution).

Qualification of non-wood MCC. Run head-to-head compression curves, Heckel plots if you use them, and dissolution on your target API loads before switching.

Future trends: what’s likely to change your MCC specs

Personalisation at scale. As 3D printing transitions from lab to pilot lines in hospital pharmacies and advanced CMOs, expect MCC-based printable recipes to formalise. You may need multiple MCC grades in the same site to support print and press operations.

Regulatory digitalisation. Pharmacopeias are accelerating harmonisation updates and digital monographs. Expect faster change-control cycles and clearer method equivalence.

Sustainability disclosure. More buyers will ask for product carbon footprints (PCFs), LCA summaries, and bio-based content documentation even for excipients—especially for consumer-facing nutraceutical brands.

Capacity investments. New lines in Asia-Pacific and Eastern Europe will gradually ease supply pressure; short-term disruptions remain possible when pulp markets are volatile.

Co-processed excipients. Expect more MCC-plus systems (e.g., MCC + super-disintegrant; MCC + silica) tuned for continuous manufacturing and very high tableting speeds.

Bottom line

MCC remains the default solid-dose excipient because it solves several formulation problems at once—binding, compressibility, and disintegration—with a benign chemistry and a deep regulatory footprint. The market is growing steadily toward ~$2.7–2.8 billion by the mid-2030s, powered by tablets and nutraceuticals, and accelerated by 3D printing and continuous workflows that prefer robust, well-characterised powders. Sourcing flexibility (wood and non-wood) gives buyers strategic options; harmonised monographs and IPEC-PQG frameworks provide a stable quality baseline. For teams building pipelines of differentiated oral products—and for operations leaders tasked with keeping lines compliant and fast—pharma-grade MCC is a safe bet with genuine upside.

References

Market size and outlook (≈$1.39B in 2024; ≈$2.75B by 2034; ≈7% CAGR). Precedence Research MCC market page (2024–2034 trajectory). (Precedence Research)

Regulatory familiarity: FDA Inactive Ingredient Database (IID). FDA IID download and FAQs; industry guidance summary on using IID and defining maximum potency. (U.S. Food and Drug Administration)

Excipient GMP/GDP frameworks. IPEC-PQG GMP Guide (Version 5, 2022) and earlier editions; IPEC Federation guideline listing; PQG guideline catalogue. (IPEC Federation)

Food/clean-label safety assessments. EFSA re-evaluation of celluloses (E460(i), etc.), including conclusion of no safety concern at reported uses; open-access EFSA article. (European Food Safety Authority)