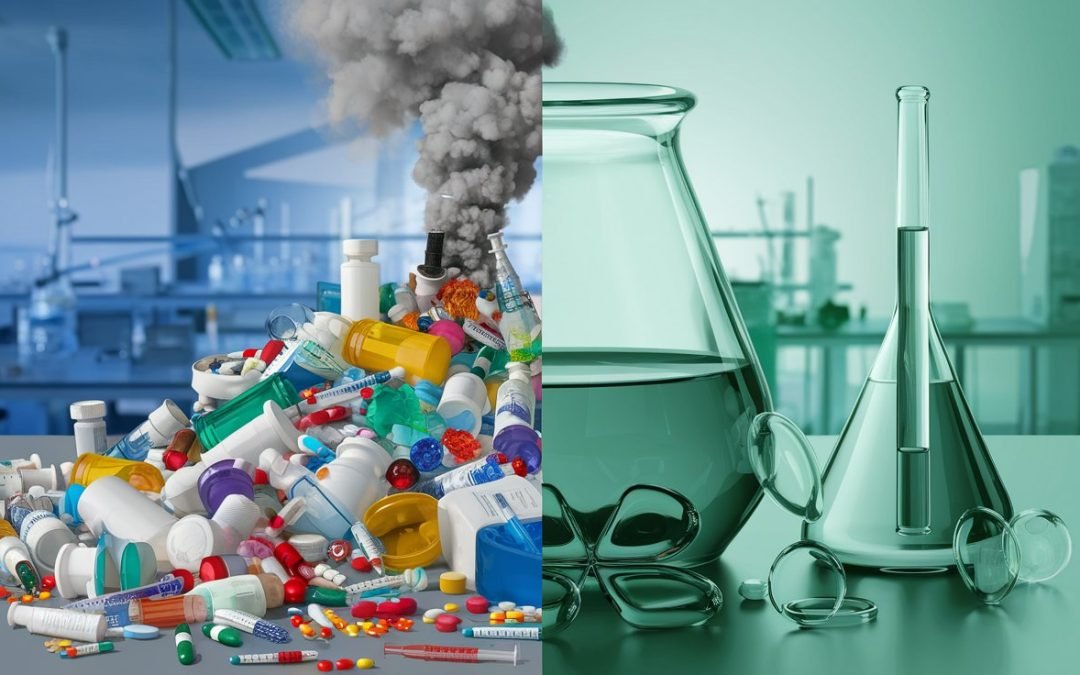

Did you know that the medicines that help us feel better might be making our planet feel worse? For every kilogram of medicine, pharmaceutical companies might generate 25 to 100 kilograms of waste! Much of this waste comes from special liquids called “solvents” used in making medicines. Traditional solvents often harm the environment, but exciting changes are happening. A green revolution is transforming how medicines are made, with eco-friendly solvents leading the charge.

Let’s explore how these earth-friendly alternatives are changing the pharmaceutical world and helping protect our planet while still creating the medicines we need!

The Hidden Problem in Your Medicine Cabinet

When you look at a pill, you see a small object that helps you feel better. What you don’t see is the massive amount of materials used to create that tiny pill. The invisible part of medicine-making has a big environmental footprint, and solvents are a major reason why.

Solvents are special liquids that help dissolve ingredients, extract useful compounds, and create chemical reactions needed to make medicines. Think of them as the “behind-the-scenes helpers” in medicine production.

In pharmaceutical manufacturing, solvents play many important roles:

- They dissolve solid materials so they can react with other chemicals

- They help extract valuable compounds from plants or other sources

- They wash away impurities during purification steps

- They create the right conditions for chemical reactions to happen

The problem? Traditional solvents used in pharma often cause serious environmental problems. A shocking 2002 U.S. Geological Survey study found pharmaceutical contaminants in 80% of streams sampled across 30 states! Many of these contaminants come from manufacturing processes that use harmful solvents.

These conventional solvents, often called volatile organic compounds (VOCs), can pollute air and water, contribute to climate change, and sometimes even harm wildlife and people. Common traditional solvents include chemicals with complicated names like dichloromethane (a suspected carcinogen), toluene, and hexane.

When pharmaceutical companies finish using these solvents, they typically have to be burned (which creates air pollution) or treated as hazardous waste (which is expensive and risky). Neither option is great for our planet.

Why Traditional Solvents Are a Big Problem

The problems with conventional pharmaceutical solvents are bigger than you might think:

Air Pollution: When solvents evaporate or are burned, they release volatile organic compounds (VOCs) that contribute to smog and air quality problems. The pharmaceutical industry is responsible for approximately 17% of carbon emissions in the industrial sector!

Water Contamination: Solvent spills or improper disposal can pollute lakes, rivers, and even underground water supplies. The 2002 U.S. Geological Survey study showed just how widespread this problem has become, with medicines and manufacturing chemicals showing up in 80% of waterways they tested.

Climate Change: Many traditional solvents have a high carbon footprint – both in how they’re made and how they’re disposed of. Making and burning these solvents releases greenhouse gases that warm our planet.

Health Risks: Workers in pharmaceutical plants might breathe in solvent vapors, which can cause headaches, dizziness, and sometimes more serious health problems with long-term exposure. Some common solvents like dichloromethane are suspected carcinogens, meaning they might cause cancer.

Resource Depletion: Most conventional solvents come from non-renewable petroleum resources, which means they can’t be replaced once used up.

The numbers tell a shocking story:

| Environmental Impact Area | Statistics for Traditional Pharmaceutical Solvents |

|---|---|

| Waste Generation | Solvents account for 80-90% of mass waste in pharmaceutical manufacturing |

| Carbon Footprint | The pharmaceutical industry contributes ~17% of industrial carbon emissions |

| Water Contamination | Pharmaceutical chemicals found in 80% of streams in a 30-state survey |

| Health Hazards | Many common solvents are classified as suspected carcinogens |

| Resource Usage | Before optimization, some medicines required up to 1,300 liters of solvent per kg of product |

These environmental and health costs have pushed scientists, companies, and regulators to look for better alternatives – and that’s where the green solvent revolution begins!

What Makes a Solvent “Green”?

Not all solvents are created equal when it comes to environmental impact. A truly green solvent needs to check several boxes:

Safety: It should be non-toxic or have very low toxicity to humans, animals, and plants.

Environmental Impact: It shouldn’t persist in the environment or cause pollution when used or disposed of.

Renewability: Ideally, it comes from renewable resources (like plants) rather than petroleum.

Energy Efficiency: It takes less energy to make and use than traditional solvents.

Effectiveness: Most importantly, it still needs to work well for making medicines!

Scientists use computer-based tools to optimize green solvent selection. These advanced technologies analyze toxicity data and environmental impact assessments to ensure companies choose the most sustainable and efficient options for specific reactions.

Types of Green Solvents Transforming Medicine-Making

The green solvent revolution isn’t just one change – it’s many different approaches working together. Here are some of the eco-friendly alternatives revolutionizing pharmaceutical manufacturing:

Water: The Ultimate Green Solvent

It might surprise you, but plain water is becoming an increasingly important solvent in pharmaceutical manufacturing! Water is non-toxic, abundant, inexpensive, and generates no harmful emissions. The challenge has been figuring out how to use water for reactions that traditionally required organic solvents.

Creative scientists have developed several approaches:

- Using high pressure and temperatures to give water different properties

- Adding special substances that help water dissolve materials it normally wouldn’t

- Creating tiny droplets of reaction mixtures suspended in water

Bio-Based Solvents: From Plants to Medicines

Another exciting category is bio-based solvents made from plant materials instead of petroleum. These include:

Ethanol: Made from fermenting plant sugars, ethanol is already widely used in pharmaceutical manufacturing. It’s biodegradable and has relatively low toxicity.

Ethyl lactate: Derived from corn or other plant starches, this solvent works well for many pharmaceutical processes and breaks down easily in the environment.

Cyrene: Made from cellulose waste (like sawdust or agricultural leftovers), this newer solvent can replace highly toxic options like NMP (N-Methyl-2-pyrrolidone) and DMF (Dimethylformamide).

Limonene: Extracted from citrus peels (a food industry waste product), this solvent smells like oranges and works well for certain extraction processes.

Bio-based solvents have a double environmental benefit – they avoid petroleum use and often make use of materials that would otherwise be waste.

Supercritical Fluids: Beyond Liquid and Gas

One of the most innovative approaches uses substances in a special state called “supercritical” – where they’re neither liquid nor gas but have properties of both. The most common example is supercritical carbon dioxide (CO₂).

When pressurized and heated to specific conditions, CO₂ becomes an excellent solvent with some amazing advantages:

- It leaves no toxic residue in medicines

- It can be completely recovered and reused

- It works at lower temperatures, saving energy

- It’s non-flammable and relatively safe to work with

Supercritical CO₂ is already used to decaffeinate coffee and extract essential oils from plants. Now pharmaceutical companies are adapting this technology to make medicines with much less environmental impact.

Deep Eutectic Solvents: An Emerging Star

A newer class of green solvents gaining attention is deep eutectic solvents (DES). These are mixtures of two or more compounds that have a much lower melting point than either compound alone. Many DES can be made from natural, biodegradable materials like plant sugars, amino acids, or even vitamin derivatives.

These innovative solvents offer several advantages:

- They’re easy and inexpensive to prepare

- Many are biodegradable and have low toxicity

- They can be customized for specific applications

- They often work at room temperature, saving energy

Amazing Success Stories: The Green Revolution in Action

The green solvent revolution isn’t just theoretical – it’s already transforming how medicines are made, with impressive results. Here are some inspiring examples:

Pfizer’s Viagra Breakthrough: One of the most dramatic examples comes from Pfizer’s production of sildenafil citrate (Viagra). Through process optimization and green chemistry principles, Pfizer reduced solvent use from an astounding 1,300 liters per kilogram of product to just 7 liters per kilogram! This 99.5% reduction shows how dramatic the improvements can be when companies commit to sustainable practices.

GlaxoSmithKline’s Green Chemistry: GSK developed a “solvent selection guide” that helps their scientists choose the greenest options for each step in medicine making. Using this guide, they’ve reduced their use of the most harmful solvents by over 75% in new processes.

Eli Lilly’s Continuous Processing: By switching to continuous manufacturing with greener solvents for some products, Eli Lilly reduced solvent use by 93%, energy consumption by 86%, and waste generation by 93% compared to traditional batch processes.

Merck’s Water-Based Antibiotics: For one antibiotic production process, Merck eliminated chlorinated solvents completely, replacing them with water. This not only reduced environmental impact but actually improved product quality and reduced manufacturing costs.

These success stories demonstrate that green solvents aren’t just good for the environment – they often make economic sense too, creating more efficient processes with less waste and lower disposal costs.

The Business Case: Green Solvents Save Money

Switching to green solvents isn’t just about helping the environment – it can also help a company’s bottom line. Here’s how eco-friendly alternatives create economic benefits:

Reduced Waste Management Costs: Traditional solvents require expensive disposal as hazardous waste. Green alternatives often can be recycled or require much less costly disposal methods.

Less Resource Use: As Pfizer’s Viagra example shows, optimized processes with green solvents can dramatically reduce the amount of materials needed, cutting purchasing costs.

Energy Savings: Many green processes run at lower temperatures or pressures than traditional methods, reducing energy bills.

Improved Safety Means Fewer Incidents: Safer solvents reduce the risk of workplace accidents and associated costs, including insurance premiums.

Brand Value and Reputation: Companies with strong environmental practices often enjoy better public perception and customer loyalty.

Future-Proofing Against Regulations: As environmental regulations become stricter, companies already using green solvents won’t need to make costly last-minute changes.

Challenges on the Path to Greener Pharma

While the green solvent revolution is making great progress, some challenges remain:

Regulatory Hurdles: One of the biggest obstacles to adopting eco-friendly solvents is the complex regulatory approval process. When a pharmaceutical company changes how a medicine is made, they must prove to regulators that the medicine remains exactly the same in terms of purity, effectiveness, and safety. This process can be expensive and time-consuming, sometimes slowing adoption despite the benefits.

Performance Gaps: Some green alternatives don’t work quite as well as traditional solvents for certain reactions, requiring process adjustments or further research.

Scale-Up Issues: What works in a laboratory might face challenges when scaled up to production levels. Engineers must solve problems like different mixing patterns, heat distribution, and material handling.

Cost Considerations: Some eco-friendly alternatives currently cost more than traditional solvents, though this gap is narrowing as production scales up and technologies improve.

Knowledge and Training: Many chemists and engineers were trained using traditional solvents and need to build experience with green alternatives.

Despite these challenges, the pharmaceutical industry continues to make progress. Every year, more green solvent processes move from research labs to production facilities.

Green Pharma Around the World: Who’s Leading the Way?

The adoption of green solvents varies around the world, with some regions moving faster than others:

North America leads in adopting green solvents due to its advanced infrastructure and strong environmental regulations. Many major pharmaceutical companies headquartered in the United States have made significant commitments to green chemistry principles.

Europe has created strong incentives for sustainable pharmaceutical manufacturing through regulations like REACH (Registration, Evaluation, Authorization and Restriction of Chemicals), which encourages safer alternatives to hazardous chemicals.

Emerging Markets like India and China, which produce many of the world’s active pharmaceutical ingredients (APIs), are increasingly prioritizing sustainability as they build new manufacturing facilities. These countries have the opportunity to implement green technologies from the ground up rather than retrofitting older plants.

Globally, the pharmaceutical industry is shifting toward bio-based options, with growing interest in technologies like supercritical CO₂ extraction and deep eutectic solvents to future-proof manufacturing processes.

The Future of Green Solvents in Pharma

The green solvent revolution is just beginning! Here are some exciting developments on the horizon:

Solvent-Free Processes: Some revolutionary approaches eliminate solvents completely! Techniques like mechanochemistry use grinding or milling instead of dissolving, while microwave and ultrasound technologies can trigger reactions without traditional solvents.

Artificial Intelligence in Solvent Selection: Computer systems are getting better at predicting which green solvents will work best for specific reactions, speeding up the transition from harmful options.

Bio-Inspired Systems: Scientists are creating systems inspired by how reactions happen in living cells – using water as the main solvent but creating special “pockets” where reactions can occur, just like in our bodies.

Circular Economy Approaches: Rather than disposing of solvents after use, more companies are creating closed-loop systems where solvents are continuously purified and reused.

New Recovery Technologies: Advanced technologies like membrane separation and special adsorbent materials are making it easier to recover and reuse green solvents, further reducing waste.

What This Means for Our Planet and Our Health

The green solvent revolution might sound like a complex technical topic, but its impacts reach far beyond pharmaceutical factories:

Cleaner Water Systems: With traditional pharmaceutical manufacturing contributing to water pollution in 80% of tested streams, the switch to greener processes could dramatically improve water quality for both wildlife and people.

Climate Protection: Reducing the pharmaceutical industry’s 17% contribution to industrial carbon emissions helps fight climate change.

Safer Workplaces: Replacing suspected carcinogens like dichloromethane with safer alternatives protects the health of workers who make our medicines.

Sustainable Medicine: As fossil fuel resources become more limited, medicines made with renewable green solvents will be more sustainable long-term.

Lower Costs (Eventually): While some green technologies cost more initially, they often reduce waste treatment costs and increase efficiency, potentially leading to more affordable medicines.

How You Can Support the Green Solvent Revolution

Even if you don’t work in the pharmaceutical industry, you can help support this important environmental transition:

Ask Questions: When you learn about new medicines, ask if they’re being produced with environmentally friendly processes.

Support Responsible Companies: Some pharmaceutical companies publish sustainability reports showing their progress on green manufacturing – consider their environmental efforts when you have medicine choices.

Spread Awareness: Share what you’ve learned about green solvents with friends and family to help more people understand why this matters.

Proper Disposal: Always dispose of your unused medications properly (not down the drain or toilet), which helps prevent pharmaceutical pollution in waterways.

Stay Informed: Follow news about green chemistry and sustainable pharmaceutical manufacturing to see how this field continues to develop.

Conclusion: A Healthier Future for Medicines and Our Planet

The green solvent revolution represents one of the most important environmental transformations happening in the pharmaceutical industry today. By replacing harmful traditional solvents with water, bio-based alternatives, supercritical fluids, and other eco-friendly options, medicine manufacturers are dramatically reducing their environmental footprint.

The dramatic improvements we’ve seen – like Pfizer cutting solvent use by 99.5% for Viagra production – show what’s possible when science and sustainability work together. These changes are helping address the troubling reality revealed by studies showing pharmaceutical pollutants in 80% of our waterways.

This revolution proves that protecting our planet doesn’t have to compete with making the medicines we need. Instead, green chemistry approaches often lead to more efficient, safer, and eventually more economical processes.

The next time you take a medicine, remember that behind the scenes, scientists and engineers are working hard to make that medicine in ways that are increasingly gentle on our environment. The green solvent revolution is creating a future where healing people and protecting our planet go hand in hand.

Green Solvent Fast Facts

- Pfizer reduced solvent use in Viagra production from 1,300 liters to just 7 liters per kilogram of product

- A 2002 study found pharmaceutical contaminants in 80% of waterways tested across 30 U.S. states

- The pharmaceutical industry contributes approximately 17% of industrial carbon emissions

- Many bio-based solvents come from agricultural waste products that would otherwise be discarded

- Water—when used with special techniques—can sometimes replace toxic solvents that were once considered essential

- Computer-based tools now help scientists select the greenest solvents for specific reactions